NEW WEBSITE FEATURE

LATHAMS INTERACTIVE VISUALISATION TOOLS NOW AVAILABLE ON TACTILE INDICATORS

At Latham Australia, our engineering team has spent decades researching, designing and refining the very highest performing expansion joint covers for constructed surfaces and joinery materials.

Latham manufactures a complete range of covers for expansion joints including for floor, floor-to-wall, wall, ceiling, and roof applications.

The floor systems are supplied with either stainless steel, full aluminium, or solid brass construction to suit a variety of architectural considerations. A wholly Australian owned and manufactured product, the Latham expansion joint range is considered the go-to option for architects and builders seeking the most trusted construction products on the market.

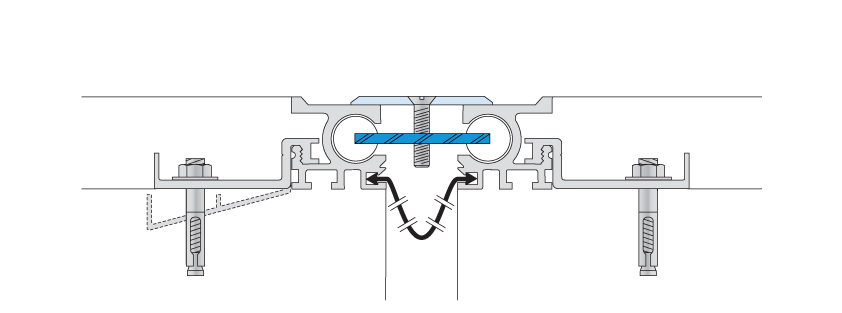

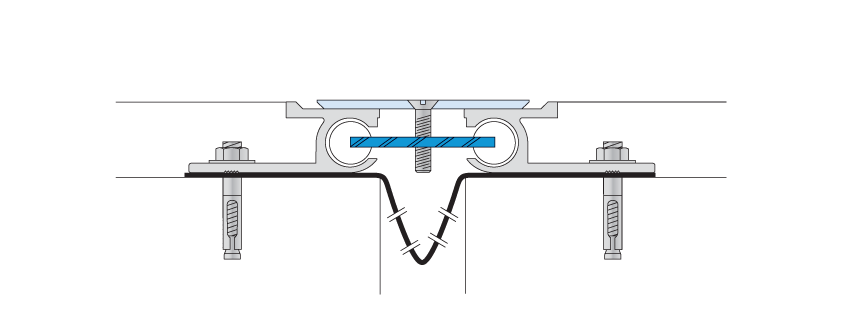

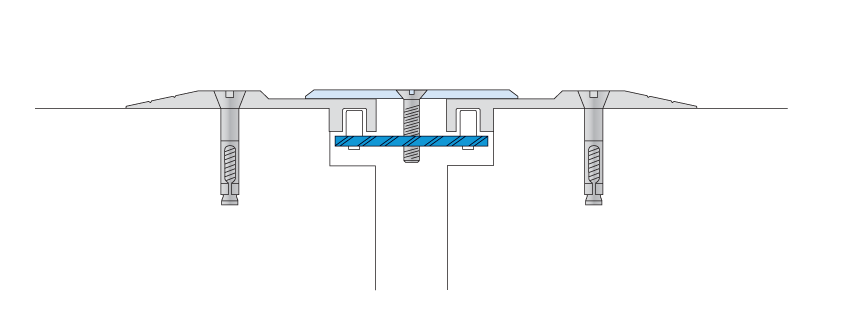

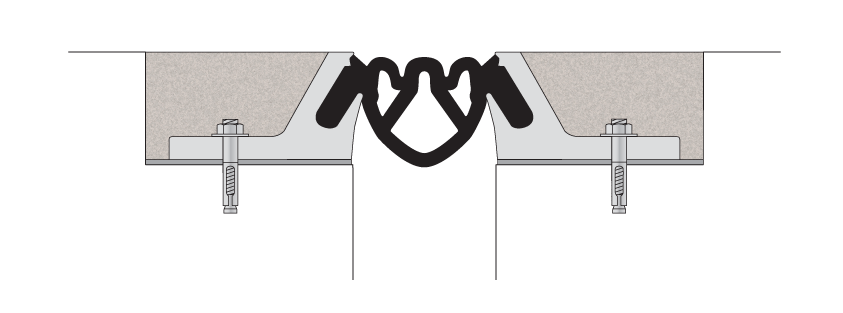

Covers are used as expansion joint gap covers for areas that experience movement within structures for example in construction joints in concrete slabs. Buildings are designed to allow movement in response to various forces including thermal expansion and contraction, long-term shrinkage of structures, as well as seismic activity in some cases. The covers are installed over these areas of movement called expansion joints, which are sometimes also referred to as movement joints, structural joints, isolation joints, control joints, or seismic joints.

Latham’s mechanical expansion joints are specifically designed to suit the conditions of the Australian environment; accommodating regular thermal contraction and expansion of building materials during seasonal variation. As global temperatures rise and changes to environmental conditions become more extreme, the installation of expansion joints in buildings has become integral to the engineering design of structures built for Australian conditions.

Operating internationally for over 70 years, we also have the knowledge, expertise, experience and on-ground presence to assist in your international market, no matter where your project is located.

Latham’s expansion joint covers can be used for both internal and external applications and accommodate movement caused by environmental conditions as well as pedestrian and vehicular traffic. Latham products are also fire rated to protect against the egress of fire through expansion joints in buildings. You can read more on the features of Latham’s expansion joint cover range here.

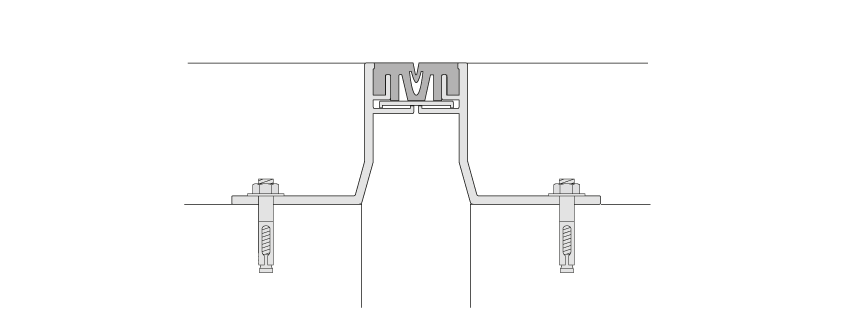

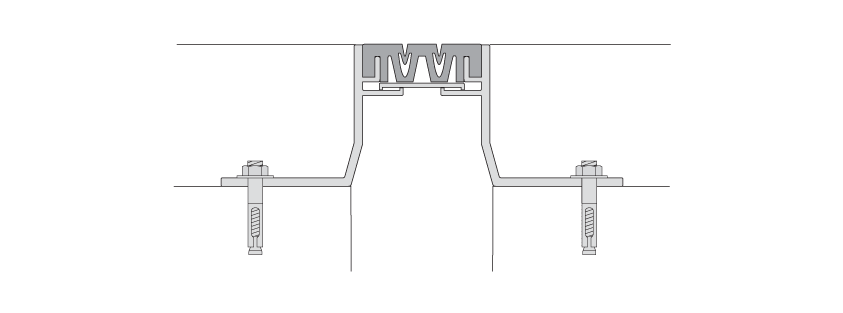

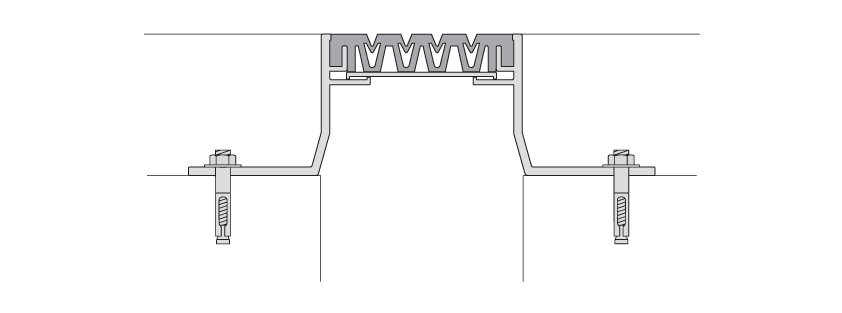

Latham has put in place an easy to recognise system to indicate what type of directional properties each system offers. This indicates whether the system can accommodate, 2-way, 4-way, or 6-way movement, ensuring you can easily select the best system for your application.

Our website includes a Product Selection Assistant. which helps you to determine the most suitable expansion joint cover for a specific application. The easy-to-follow selection tool provides a recommendation based on criteria including the joint width, floor finish type and depth, and anticipated joint movement.

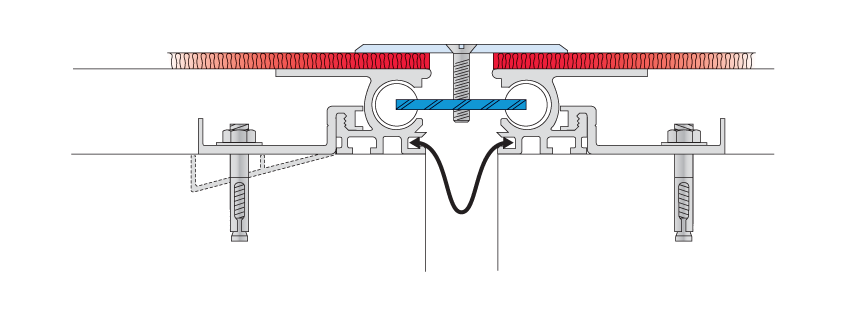

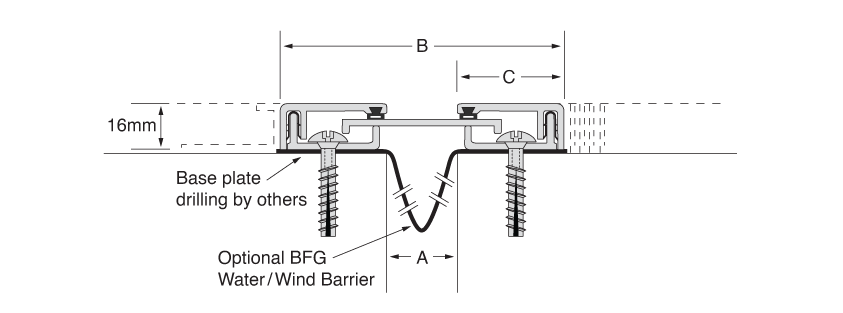

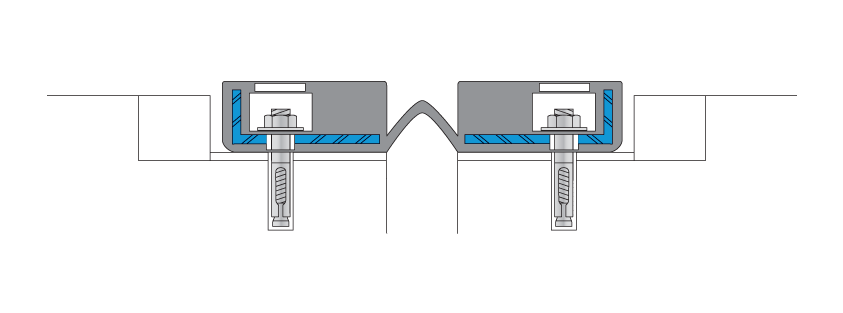

The Latham Ultimate Series offers a range of expansion joint covers suited to most floor and floor-to-wall applications. The systems offer generous thermal and structural movement and shrinkage and will accommodate limited seismic movement. Systems are available in stainless steel, aluminium and brass to complement most facets of architectural design.

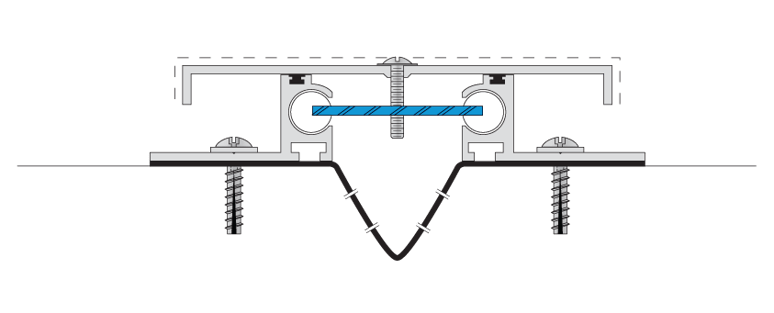

The Latham Flat-Lines Series NO BUMP expansion joint covers are specifically designed for applications where a bump in the floor can not be tolerated. These systems offer limited movement but ensure that there is no bump for beds or trolleys that pass over the cover. The systems offer thermal and structural movement and shrinkage and will accommodate limited seismic movement.

The Latham Surface-Line Series of expansion joint covers are specifically designed for applications where recesses are not possible either through the design of the building, the substrate material or where recesses have been overlooked. The Mechanical Systems in the range allow 6 way movement, whilst the surface fixed products generally cover 2 directional movement.

The Latham Carpet-Line Series offers a range of expansion joint covers that are suited to most floor and floor-to-wall applications in carpet flooring. The systems offer generous thermal and structural movement and shrinkage and will accommodate limited seismic movement.

The Latham Wall-Line Series of expansion joint covers are specifically designed for wall and ceiling applications. There are a variety of systems which range from spring fixings details to mechanical fixed details in full aluminium or aluminium and Santoprene inserts The systems offer thermal and structural movement and shrinkage and will accommodate limited seismic movement.

All the Roof-Line Series joint covers come standard with a water/wind barrier and top seal gaskets for the centre plate screw of the flat roof cover. All flat roof and roof-to-parapet covers are supplied with 1 splice plate per full length which is for installation over the junction between 2 plates to maintain water tightness.

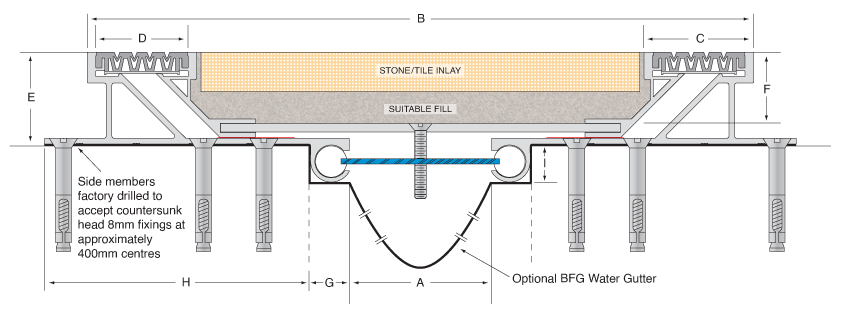

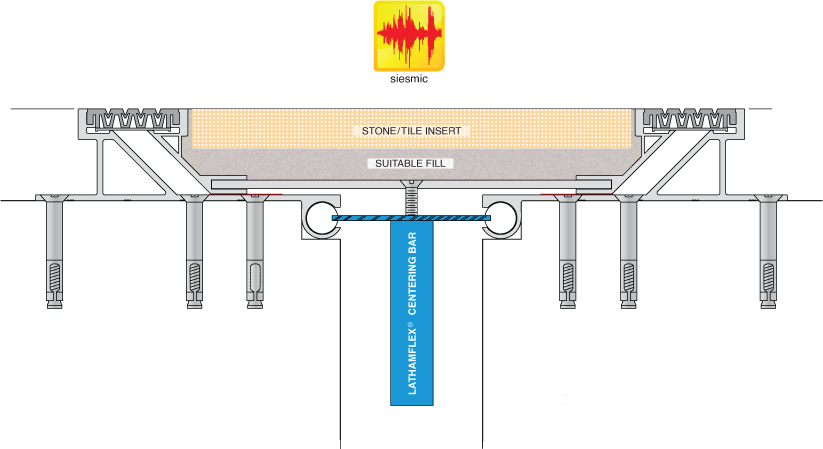

The Latham PAVA In-Lay Series joint covers offer an architecturally appealing outcome particularly for wider joint systems. They are suited to sand cement bed tilling and cement tile and paving applications, but can be equally effective with other forms of floor finishes like, carpet, vinyl, rubber, epoxy and even direct stick carpet. The systems offer generous thermal and structural movement and shrinkage.

The Latham Light Duty 30 Series of expansion joint covers incorporate Santoprene and Neoprene inserts to allow limited movement in internal light duty applications. They are suited to floor, floor-to-wall, wall and ceiling applications where limited movement capabilities are required. The systems interact with each other, which means a similarly designed system can be used in the floor, wall and ceiling if required.

The Latham Light Duty 50 Series of expansion joint covers incorporate Santoprene and Neoprene inserts to allow limited movement in internal light duty applications. They are suited to floor, floor-to-wall, wall and ceiling applications where limited movement capabilities are required. The systems interact with each other, which means a similarly designed system can be used in the floor, wall and ceiling if required. The systems offer 4 directional movement and limited thermal and structural movement.

The Latham Light Duty 70 Series of expansion joint covers incorporate Santoprene and Neoprene inserts to allow limited movement in internal light duty applications. They are suited to floor, floor-to-wall, wall and ceiling applications where limited movement capabilities are required. The systems interact with each other, which means a similarly designed system can be used in the floor, wall and ceiling if required.

The Latham Heavy Duty Series offers a range of aluminium and stainless steel expansion joint covers suited to most heavy duty pedestrian car and truck applications. The systems in the range offer 6 way movement, whilst offering generous thermal and structural movement and shrinkage and will accommodate limited seismic movement.

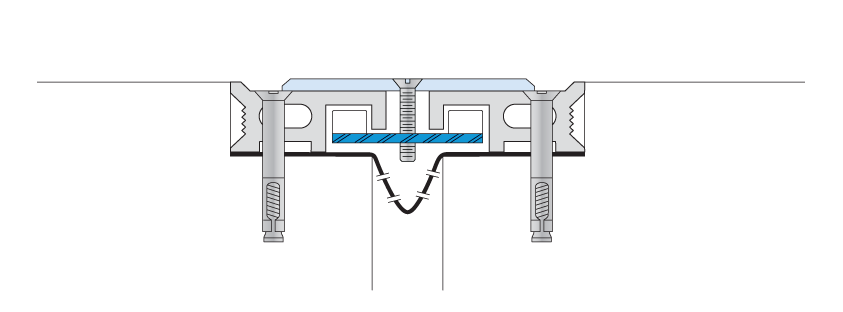

The Latham Car Joint Series includes the RTJ-1 Series and the USETM Series.They are designed for car parks, driveways and roof top parking structures. The RTJ-1 Series standard system is supplied with 6mm thick aluminium cover plates. This series is available with custom modified systems for heavier applications including delivery bays, refuse vehicle areas and other applications.

The Latham Bridge & Roadway Series expansion joints are designed to control movement in roadway and bridge applications. These systems are designed for long durability, to be water tight and the smooth surface is designed to be wear resistant whilst reducing the likelihood of skidding that is often associated with other style roadway and bridge joints.

The Latham range of seismic expansion joint covers, are designed to accommodate extreme movement that occurs during seismic activity and earthquakes. They are also commonly used in modern hi-rise structures, that experience excessive movement during very high winds like typhoons, hurricanes and cyclones.

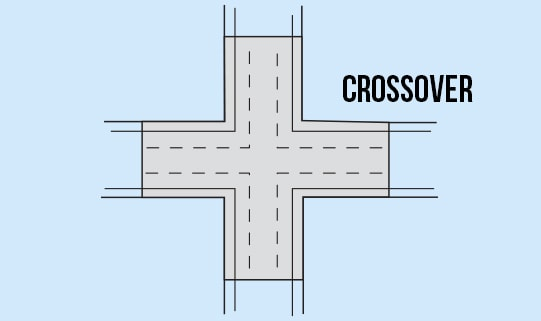

For effective performance, corners, crossovers and tees should be factory fabricated in a complete unit. This ensures that gaps don’t form between the separate cover plates. When you choose to have the item fabricated, all cover plates and side members will be factory welded, with virtually seamless welds. This service is available for all mechanical floor and floor to wall expansion joint covers.

Cover Plates are available in various sizes, profiles and finishes to suit applications where little or no movement is anticipated. The Cover Plates are surface mounted and simply cover the gap or trench in the floor, wall or ceiling to provide an attractive finish. Cover Plates are available in Stainless Steel, Brass, or Aluminium.

Latham offer Fire Rated Systems (Barriers) to be used in conjunction with the Latham Flexible Mechanical Expansion Joint Covers. All have been tested and classified by one or more of the following independent, internationally recognised authorities: US Underwriters Laboratories Inc. (USA), Omega Point Laboratories Inc. (USA), listed by Warnock Hersey International Incorporated (USA) and listed by The State of California State Fire Marshal.

Try Our Selection assistant

View product information & optional extras

%202.jpg?width=480&height=350&name=Latham-7875%20(1)%202.jpg)

Learn more about our architectural specifications

Use the form below to get in touch and one of our consultants will get back to you as soon as possible.

14 Tennyson Road Gladesville 2111 NSW Australia

Phone: +61 2 9879 7888

Fax: +61 2 9879 7666

info@latham-australia.com