NEW WEBSITE FEATURE

LATHAMS INTERACTIVE VISUALISATION TOOLS NOW AVAILABLE ON TACTILE INDICATORS

Stair tread nosings need to stand out from the surrounding parts of the stairs. This is an important safety issue to ensure the visibility and safe usage of steps and stairs by vison-impaired pedestrians. The “Luminance” of a surface measures brightness. The degree of visibility of one surface against another is measured as “Luminance Contrast”.

Luminance Contrast is the ratio of the Luminance Reflectance Values (LRV) of a particular colour and style of Stair Tread Nosing and the surface on which it is installed. There is an industry-standard formula which is used to calculate the degree of contrast in every case. The Standards AS 1428.1 -2021 and AS 1428.1 – 2009 both set the minimum Luminance Contrast for compliance.

Clearly, both the LRV of the floor surface and the LRV of the Stair Tread product must be known, or there is no way to calculate the contrast. Both possible combinations, of dark stair tread nosings on light floor coverings and light stair tread nosings on dark floor coverings, can deliver Standard-compliant contrast values.

Lathams provides a user-friendly way to determine which of our abrasive insert colours (only in the single strip, full-abrasive style) will provide a compliant degree of contrast, given the LRV for your chosen floor surface. We have set up a simple tool to interpret the calculations for you. This tool is also available via the product pages of our stair tread nosings. The user enters the LRV for their floor surface. The contrast between that LRV and the Full-Abrasive Latham products in their possible colours is calculated. We display only those Stair Tread Nosing colours which will deliver at least the minimum contrast requirement under the standard. Contact Lathams if you need information on Luminance Contrast for the more traditional, multiple-stripe styles of Stair Tread Nosings.

You can find the Luminance Contrast calculation tool here:

Lathams’ Silicon Carbide abrasive infills are offered in a variety of colours, in combination with our selection of different metal tread profiles. This gives our customers the widest range of product choice in the industry. We have engaged the NATA-accredited Optics and Radiometry Laboratory at the University of NSW School of Optometry and Vision Science to conduct independent determinations of the Luminance Reflectance Values of all our possible combinations.

This laboratory testing provided an independently determined Luminance Reflectance Value for all the Latham stair tread nosing products. The specific values for each combination of tread style and infill colour can be found here: Asbra Safety Stair Treads Luminance Testing Values

That information gives you all that you need for the Stair Tread Nosing part of the calculation. Once you know the LRV of your chosen floor surface, you can calculate the contrast using the method in the Standard. Or you can just use our simple calculator tool to present you with only the compliant colours for use with that flooring.

Sometimes, although it is rare, the supplier may publish the LRV for their flooring surface. Some professional architecture and design practices have invested in their own spectrophotometer equipment, but this can be extremely expensive, especially for small firms with irregular need to know these facts.

Lathams have, in our Sydney plant, a Spectrophotometer capable of taking the readings necessary as detailed in AS 1428.1-2009 Appendix B and AS/NZS 1428.4.1:2009 Appendix E. Lathams’ instrument is properly maintained and calibrated by a NATA Accredited Authority.

When builders and architects ask us, Lathams can provide indicative luminance testing results for samples of your chosen flooring. We will provide the test results and the luminance contrast between the supplied sample and our stair tread nosings or Tac Tile indicators.

You can send us a request here to have Lathams test the LRV of your floor finish. We will also indicate which colours of Latham Stair Tread Nosings will meet the Luminance Contrast requirements of the Standard when used with the tested floor surface. Once you know the LRV of your floor finish, clicking the Calculation Tool above will let you repeat the analysis of complying colours at any time.

Find out more about this service or request more information on LRV testing by Latham Australia. Simply email techreq@latham-australia.com

Latham Silicon Carbide inserts for Treads have been independently tested by The University Of New South Wales Optics & Radiometry Laboratory School of Optometry and Vision Science, a National Association of Testing Authorities (NATA) accredited facility in accordance with Appendix B of AS 1428.1-2009 (specifically Clause B3 Measurement of Luminance Contrast – Laboratory) for dry and wet applications.

Instrument used: Spectrophotometer calibrated by a NATA Accredited Calibrating Authority, which complies with Clause B3.2 of AS 1428.1-2009.

Method: Eleven measurements were made on the tread section (aluminium or brass retainer) and the infill of each sample and the mean value calculated. The total area of each sample was determined along with the area of tread (retainer) and infill. The mean luminous reflectance of each sample was then determined from the sum of mean luminous reflectance of each component, as a proportion of the area as calculated above. Measurements are made in wet and dry states.

AS 1428.1-2009 under Appendix B (informative) sets out the method to determine the minimum Luminance Contrast between 2 adjoining surfaces by using their luminous reflectance values. The Standard refers to the Bowman-Sapolinski Equation (An Improved Metric for Visual Differentiation using Colour-modified Clinical Eye Charts, Redeemer Baptist School North Parramatta Australia Sapolinski,J., August 2009.).

It is important to note that this Appendix B of AS 1428.1-2009 is Informative, Standards Australia publication Standardisation Guide 003: For Standards and Other Publications, has the following definition for the term informative.

Informative is a term used to describe an element (clause, note or appendix) of a Standard that gives additional information, recommendations and/or guidelines, i.e. is of a non-mandatory nature. Where a Standard contains both mandatory and informative elements, the informative material is usually aimed at explaining the mandatory requirements and helping the user to understand and comply with the Standard.

A copy of the full NATA Accredited Testing Facilities results is available by contacting Latham Australia.

| Colour Description | Dry Luminance Reflective Value | Wet Luminance Reflective Value |

|---|---|---|

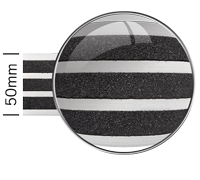

| All Black Latham Suregrip™ Insert (Striped) | 5.00% | 5.18% |

| All White Latham Supagrit™ Insert (Striped) | 45.76% | 46.58% |

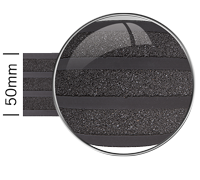

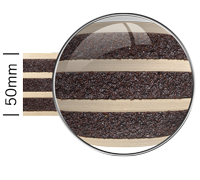

| All Black Latham Suregrip™ Insert (Solid 50mm) | 4.45% | 4.65% |

| All White Latham Suregrip™ Insert (Solid 50mm) | 35.67% | 36.22% |

| Colour Description | Dry Luminance Reflective Value |

Wet Luminance Reflective Value |

|---|---|---|

| Black Latham Suregrip™ Insert (Striped) | 28.99% | 28.89% |

| Teal Latham Supagrit™ Insert (Striped) | 31.19% | 31.94% |

| Blue Latham Supagrit™ Insert (Striped) | 32.01% | 32.91% |

| Brown Latham Supagrit™ Insert (Striped) | 32.75% | 32.30% |

| Terracotta Latham Supagrit™ Insert (Striped) | 34.18% | 33.55% |

| Teak Latham Supagrit™ Insert (Striped) | 35.75% | 35.26% |

| Cactus Green Latham Supagrit™ Insert (Striped) | 36.16% | 326.02% |

| Blue Grey Latham Supagrit™ Insert (Striped) | 37.11% | 36.02% |

| Silver Grey Latham Supagrit™ Insert (Striped) | 37.79% | 37.67% |

| Buff Latham Supagrit™ Insert (Striped) | 40.81% | 41.48% |

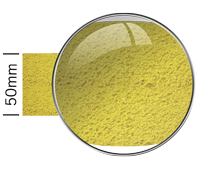

| Safety Yellow Latham Supagrit™ Insert (Striped) | 41.41% | 40.40% |

| Off White Latham Supagrit™ Insert (Striped) | 50.17% |

48.26% |

| Rose Latham Supagrit™ Insert (Striped) | 47.10% |

46.85% |

| Smoke Latham Supagrit™ Insert (Striped) | 41.58% |

42.71% |

| Plum Latham Supagrit™ Insert (Striped) | 40.62% |

40.50% |

| Lumo Glow in the Dark Latham Supagrit™ Insert (Striped) | 51.62% | 53.06% |

| Colour Description | Dry Luminance Reflective Value |

Wet Luminance Reflective Value |

|---|---|---|

| Black Latham Suregrip™ Insert (Solid 50mm) | 4.45% | 3.69% |

| Brown Latham Supagrit™ Insert (Solid 50mm) | 6.19% | 8.63% |

| Blue Latham Supagrit™ Insert (Solid 50mm) | 7.51% | 7.73% |

| Terracotta Latham Supagrit™ Insert (Solid 50mm) | 8.33% | 8.05% |

| Cactus Green Latham Supagrit™ Insert (Solid 50mm) | 11.58% | 11.01% |

| Teak Latham Supagrit™ Insert (Solid 50mm) | 12.31% | 12.02% |

| Teal Latham Supagrit™ Insert (Solid 50mm) | 15.49% | 14.74% |

| Blue Grey Latham Supagrit™ Insert (Solid 50mm) | 16.71% | 18.44% |

| Silver Grey Latham Supagrit™ Insert (Solid 50mm) | 18.71% | 16.61% |

| Buff Latham Supagrit™ Insert (Solid 50mm) | 21.15% | 21.35% |

| Safety Yellow Latham Supagrit™ Insert (Solid 50mm) | 22.69% | 22.20% |

| Off White Latham Supagrit™ Insert (Solid 50mm) | 36.56% | 36.01% |

| Rose Latham Supagrit™ Insert (Solid 50mm) | 30.32% | 27.98% |

| Smoke Latham Supagrit™ Insert (Solid 50mm) | 25.93% | 25.56% |

| Plum Latham Supagrit™ Insert (Solid 50mm) | 18.57% | 18.56% |

| Lumo Glow in the Dark Latham Supagrit™ Insert (Solid 50mm) | 38.75% | 39.08% |

| Colour Description | Dry Luminance Reflective Value |

Wet Luminance Reflective Value |

|---|---|---|

| Black Latham Suregrip™ Insert (Striped) | 18.66% | 17.76% |

| Brown Latham Supagrit™ Insert (Striped) | 19.55% | 22.59% |

| TerracottaLatham Supagrit™ Insert (Striped) | 20.92% | 20.41% |

| Blue Latham Supagrit™ Insert (Striped) | 21.56% | 22.94% |

| Cactus Green Latham Supagrit™ Insert (Striped) | 24.02% | 23.04% |

| Teak Latham Supagrit™ Insert (Striped) | 24.18% | 24.29% |

| Teal Latham Supagrit™ Insert (Striped) | 25.86% | 25.47% |

| Blue Grey Latham Supagrit™ Insert (Striped) | 26.44% | 28.36% |

| Silver Grey Latham Supagrit™ Insert (Striped) | 27.25% | 25.42% |

| Buff Latham Supagrit™ Insert (Striped) | 27.52% | 26.68% |

| Safety Yellow Latham Supagrit™ Insert (Striped) | 30.57% | 30.53% |

| Off White Latham Supagrit™ Insert (Striped) | 37.67% | 38.75% |

| Rose Latham Supagrit™ Insert (Striped) | 36.48% | 34.53% |

| Smoke Latham Supagrit™ Insert (Striped) | 33.37% | 32.56% |

| Plum Latham Supagrit™ Insert (Striped) | 30.70% | 28.52% |

| Lumo Glow in the Dark Latham Supagrit™ Insert (Striped) | 40.82% | 40.31% |

| Colour Description | Dry Luminance Reflective Value | Wet Luminance Reflective Value |

|---|---|---|

| Black Latham Rufazel™ Product | 3.85% | 3.14% |

| Yellow Latham Rufazel™ Product | 45.76% | 46.58% |

Use the form below to get in touch and one of our consultants will get back to you as soon as possible.

Modal body text goes here.

Submit the following to receive your content download.

14 Tennyson Road Gladesville 2111 NSW Australia

Phone: +61 2 9879 7888

Fax: +61 2 9879 7666

info@latham-australia.com