NEW WEBSITE FEATURE

LATHAMS INTERACTIVE VISUALISATION TOOLS NOW AVAILABLE ON TACTILE INDICATORS

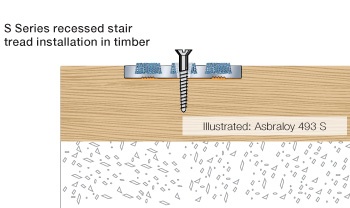

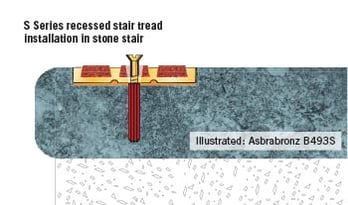

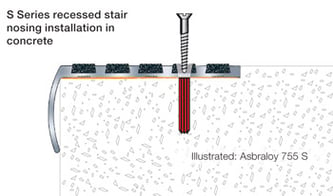

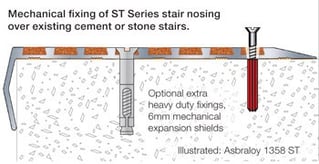

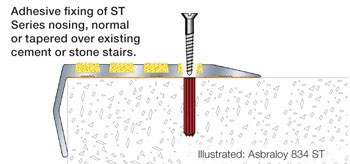

Secure and rigid fixing is essential for safe, satisfactory performance. All movement and rattle must be eliminated. Latham Asbraloy and Asbrabronz Stair Tread Nosings and Inserts are generally supplied factory cut to length complete with countersunk holes screws and plugs, on request the

Unless otherwise specified with order

Latham Australia does not recommend the use of adhesive alone for the installation of stair tread nosings as the bond can not be guaranteed without mechanical fixings.

When using Latham Titazel Thixotropic 2 Part Epoxy Adhesive for fixing Asbraloy and Asbrabronz Stair Tread Nosings and Inserts to flat and level substrate, it may be possible to increase the distance between the screw fixing locations, the maximum span that should be considered in 1000mm.

Asbraloy and Absrabronz insert treads can be installed in virtually any hard floor finish, including stone, tile concrete, terrazzo and timber. When insert

Recently the updated Australian Standard AS 1428.1-2009 indicates a maximum

A correctly formed groove for the

Latham recommends the use of Titazel Thixotropic Epoxy Adhesive for the installation of tread inserts or Latham

S Series Recessed Treads and Inserts are designed to be installed into a preformed recess. This can be cut or cast in concrete, cut into timber treads or achieved when tile etc are being installed on top of a concrete or similar (when the Stair Tread* is being installed

It may be necessary to increase the height of the set down (particularly if the

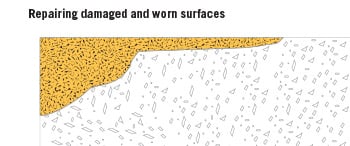

Filling the recess should be achieved using Latham Titazel RA-1 Filling and Levelling Compound or similar suitable product. The recess should be filled and levelled to a suitable level for the selected stair tread profile (see product depth information in the relevant table for the selected product selected), an allowance also needs to be made for Latham Titazel Thixotropic Epoxy Adhesive or

Once this has been done proceed Basic Stair Tread Installation Details. *Insert Treads are considered not suitable for carpet installation by Latham Australia, although there is not a problem with Stair Treads, see the information below.

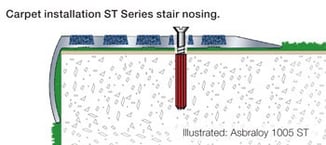

ST Series Treads can be installed over concrete, tile, pavers, stone, timber and other solid surfaces. After ensuring the surface is of good finish and even (if not refer to information on repairing damaged or worn surfaces) proceed to Basic Stair Tread Installation Details. When the Stair Tread* is being installed in conjunction with carpet, see reference to carpet and vinyl installations below.

SB Series Treads are designed to be installed on concrete or timber applications as a surface mounted profile, where vinyl or direct stick carpet is being installed. The 3mm straight edge combined with the 2mm x 45º bevel ensures a smooth transition from the floor finish to tread.

If levelling or packing is required, see the details under S Series Treads and Inserts. Once this has been done, proceed to instructions in Basic Stair Tread Installation Details.

ST Series Treads can be installed over carpet providing the carpet is firm and the substrate is good and a secure fixing can be made. Obviouslywhen a tread is being installed over carpet, adhesive can not be used. The following installation methods should be followed, although it is advisable to use a carpet punch to punch a hole through the carpet in the location where the hole is to be drilled, this will helpto ensure that the carpet is not pulled by the spinning drill. To carry out this installation it may be necessary to shave the carpet pile or to install continuous solid packers under the back edge of the tread. This style of installation generally can not be used on treads where carpethas underlay.

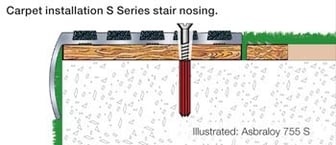

S Series Treads are designed to be installed into a preformed recess or on a packer in a carpet and underlay application, please see the attached detail; the timber packer should be securely fixed to the substrate.

Light Duty LDT, LDAS, Light Duty Resilient and Inox Series Stair Treads should be installed in a similar fashion to the details listed for the other

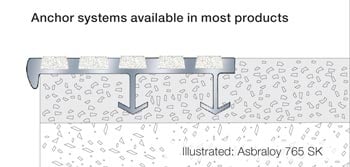

Cast-in fixing for tile, slate, exposed aggregate, concrete, etc. Asbraloy anchors provide ready fixing, eliminating wasted effort in drilling holes in fresh concrete. The cast in

When specified at

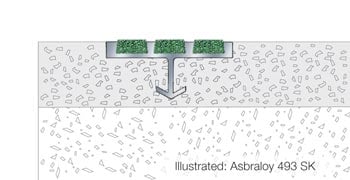

When installing 493SK, this is set back from the edge of the tread, there is no specific requirement for this

When specified with order, Latham

It may be necessary to increase the height of the set down (particularly if the

The treads are installed as detailed above. See Tredlite LED Decorative Nosing for further details on the LED Lighting and contact Latham Australia for further connection and installation detail.

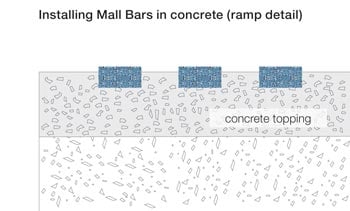

Mall Bars are designed to be installed/cast

The Mall bar is worked into the topping, which is best trowel cut whilst wet to assist with working the mall bar

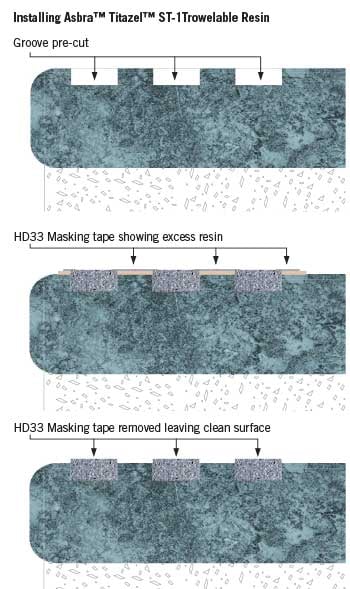

Asbra Titazel ST-1 Trowelable Resin Safety Tread Kits can be installed in virtually any hard floor finish, including stone, tile concrete and timber. When ST trowelled bars are being installed, there has been no specific information on what this set back from the edge of the tread should be, although industry practice has been to set the inserts back 25-30mm. Recently the updated AS 1428.1-2009 indicates a maximum

When installing these in ramps or footpaths it is recommended that they are installed at a maximum of 150mm centres to

ST-1 can also be applied as a surface coating this is simply trowelled

Use the form below to get in touch and one of our consultants will get back to you as soon as possible.

Modal body text goes here.

Submit the following to receive your content download.

14 Tennyson Road Gladesville 2111 NSW Australia

Phone: +61 2 9879 7888

Fax: +61 2 9879 7666

info@latham-australia.com