With tile installation, some elements often go unnoticed despite playing a crucial role in ensuring the longevity and integrity of the finished project. One of these unsung heroes are tile control strips - a fundamental component that are indispensable in tile installation projects.

Understanding Tile Expansion Strips

Expansion strips are flexible materials installed between adjacent tiles or at transitions between different flooring materials.

Expansion strips are flexible materials installed between adjacent tiles or at transitions between different flooring materials.

The primary function of control strips is to provide a buffer zone to relieve stress caused by thermal expansion and contraction, as well as substrate movement, which can result from settling, vibrations, or changes in the building's foundation. Without proper control strips, these forces can exert immense pressure on the tiles, leading to unsightly cracks, lippage, and tile popping.

Control strips contribute to the overall stability of the tile installation by reducing the risk of tenting or debonding, where tiles or topping lift from the substrate due to internal stresses. By allowing for controlled movement, expansion strips help to distribute forces evenly throughout the tiled surface, minimising the risk of localised damage and ensuring a long-lasting and durable installation.

Estimating Flooring and Pavement Movement

It is possible to calculate movements resulting from the regular influences of thermal contraction and expansion and swelling and shrinkage caused by changes in humidity.

A linear relationship exists for thermal movements known as the linear coefficient of thermal expansion. These are best expressed in millimetres per metre per degree Celsius temperature change. Average values are given below:

- Concrete with gravel aggregate 0.009 to 0.012

- Cement-based mortar 0.010 to 0.011

- Granite 0.008 to 0.010

- Marble 0.004 to 0.006

- Ceramic tiles 0.004 to 0.008

Using these coefficients, calculating thermal movement is straightforward with the following formula and example:

- Expected temperature change (between mid-Winter and peak Summer) – 40C

- Width of tile band – 4.5 metres

- Coefficient of expansion (for ceramic tiles) – 0.004 - 0.008

Absolute thermal movement: 0.008 x 40 x 4.5 = 2.16mm

It must be emphasised that this hypothetical dimension of 2.16 millimetres represents the sum of expansion and contraction. Assuming that the paving materials are installed at an average temperature of 25C on a site subject to groundwater freezing in winter, contraction from the initial condition will account for 0.9mm and expansion for 1.26mm of the total.

While tiles and natural stone swell and shrink in response to wetting and drying, movement for glazed tiles is so slight that it is rarely tested or quoted in manufacturers technical literature.

Expansion joint separations

These calculations are used to inform recommended expansion joint spacings and the distance between adjacent expansion joints. The Australian Standard recommends intermediate “stress-relieving joints” in internal tile work at 8 to 10 metre centres and in external tiled pavements at centres of approximately 4.5 metres. Australian NATSPEC recommends rectangular bays at 3 metre to 5 metre spacings.

Lathams' recommendation is 4.5m x 4.5m internally, use a 6mm wide neoprene strip, reducing to 3.0m x 3.0m externally using a 12mm wide control strip.

Expansion Control Strip Selection

Latham X-Pansion Strips are capable of absorbing expansion and compression equivalent to 16% to 20% of the undeformed width of their elastic neoprene cores. Thus, 12mm joints can be compressed to about 10mm and expanded to about 14mm, while 6mm joints can be compressed to about 4.75mm and expanded to about 7.25mm.

Installation of Expansion Control Strips

Latham X-Pansion Strips are installed at the same time as laying the wet under-bed or adhesive, ensuring positive anchorage and a gauge for the paving thickness. Installers should ensure that the substrate is clean, level, and free of debris before installing expansion strips to ensure a secure bond and optimal performance.

Installation requires no on-site work other than cutting to length where necessary.

---------

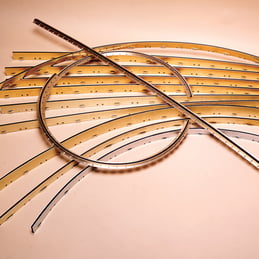

Latham X-Pansion Strips are available in aluminium, zinc, stainless steel and brass with two different profile widths. Neoprene sections are available in 6mm or 12mm sections, three different colours and twenty-two standard depths from 4mm to 125mm, to suit the exact depth of tile to be used.

Latham X-Pansion Strips are available in aluminium, zinc, stainless steel and brass with two different profile widths. Neoprene sections are available in 6mm or 12mm sections, three different colours and twenty-two standard depths from 4mm to 125mm, to suit the exact depth of tile to be used.

Non-standard sizes can be accommodated through consultation with the Latham technical team.

With 1,056 standard Latham X-Pansion Control Strips that can be specified, and all manufactured in the Sydney suburb of Gladesville, no other supplier of flooring products can match Latham Australia for variety, quality and project certainty.

To find out more about Latham products, please visit latham-australia.com. To talk to a Latham product expert, call 1300 LATHAM (528 426) or email sales@latham-australia.com.

-1.png)