Buildings are designed to allow movement in response to various forces including thermal expansion and contraction, long-term shrinkage of structures and, in some cases, seismic activity.

To accommodate this movement, expansion joints are separations between structural elements – gaps, that allow structural elements to move and reduce stresses that may occur. In many cases, these gaps are filled with surface-mounted expansion joint cover systems that conceal the gaps and provide an attractive finish while accommodating movement, ensuring walkability, waterproofing and general serviceability of the structure.

To accommodate this movement, expansion joints are separations between structural elements – gaps, that allow structural elements to move and reduce stresses that may occur. In many cases, these gaps are filled with surface-mounted expansion joint cover systems that conceal the gaps and provide an attractive finish while accommodating movement, ensuring walkability, waterproofing and general serviceability of the structure.

Expansion joint covers are an essential part of today’s construction industry.

The challenge for builders is that one expansion joint cover might look like another. Metal sections are attached to either side of the expansion joint and a cover spans the gap and conceals any movement across the joint.

Simple enough. What could possibly go wrong?

Like many things, it’s what you don’t see that’s important.

How Do Latham Expansion Joints Work?

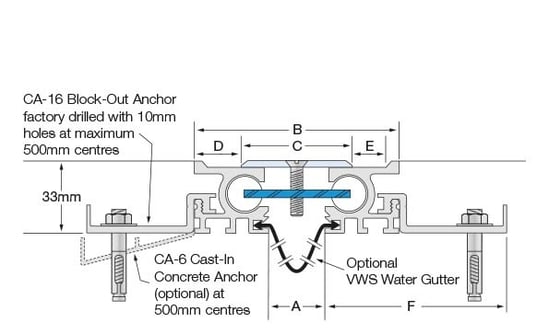

The expansion joint cover must accommodate the full range of movement anticipated by the construction engineer. This is rarely simple 2-way movement and may be multi-directional six-way movement. Furthermore, the cover unit must be free to move horizontally, vertically, and horizontally in shear without damaging the surrounding concrete and paving, deforming the cover plate, or shearing the screws holding the cover plate in place.

That requires surprisingly complex engineering and, as it sits under the cover plate, it’s hidden from sight. It won’t be visible when initially installed, but once there’s movement across the joint, you’ll soon find out whether you’ve bought a lemon.

At Latham Australia, our engineering team has spent decades researching, designing and refining the very highest performing expansion joint covers for constructed surfaces and joinery materials.

The key to our system is a centering bar which consists of two wear resistant spheres fastened at opposite ends of a flat spring steel bar. These act as lubrication free bearings, minimising wear on the aluminium and brass tracks in which the mechanism constantly moves. The bars are positioned diagonally across the joint opening. The spring steel centering bar holds the cover plate central and the fixing screws tight.

Why You Should Choose Latham Expansion Joint Covers

When you select Latham Self Aligning Flexible Mechanical Expansion Joint Covers, you are taking advantage of a unique solution to the problem of keeping joint covers firmly anchored despite movement between sections of concrete flooring. This ensures a long-lasting, trouble free and stable floor base.

When you select Latham Self Aligning Flexible Mechanical Expansion Joint Covers, you are taking advantage of a unique solution to the problem of keeping joint covers firmly anchored despite movement between sections of concrete flooring. This ensures a long-lasting, trouble free and stable floor base.

Whatever your project, Latham Flexible Mechanical Expansion Joint Covers are available in a wide variety of styles and can be fabricated to almost any width or required joint movement. Optional water gutters or fire barriers are part of the totally trouble-free joint system. Latham also manufactures expansion joint covers for walls and ceilings as well as for floor-to-wall joints. Truly – we've got you covered.

Is it any wonder that the Latham expansion joint range - a wholly Australian-owned and manufactured product, is considered the go-to option for architects and builders seeking the most trusted construction products on the market?

To find out more about Latham products, please visit www.latham-australia.com. To talk to a Latham product expert, call 1300 LATHAM (528 426) or email sales@latham-australia.com.