When it comes to robotics, the construction industry has remained relatively untapped due to the difficult nature of automating manual construction tasks. However, the industry is on the cusp of a revolution: a string of innovations and developments in the field of construction robotics this year are paving the way for exciting developments that will shape the future of our industry.

For construction workers, innovations in construction robotics provide plenty of opportunities for improved working conditions, whether through automating repetitive or dangerous tasks such as bricklaying or truck loading, or reducing Work Health and Safety risks and improving construction quality. Likewise, for project managers, the rise of construction robotics could lead to more streamlined project management, faster delivery, more predictable timelines, and increased productivity.

From robotics in building construction to robotic welding, automation in construction is paving the way for an exciting future in the construction industry. Here are 7 developments in construction robotics that could revolutionise our industry – for the better.

1. Bricklaying robot

One of the most promising innovations in the construction robotics industry is the bricklaying robot, also known as SAM (Semi-Automated Mason). Using a mechanical arm, SAM can pick up bricks, cover them with mortar and lay them down – all workers need to do is load the machine with bricks, and scrape off any excess mortar.

SAM can lay between 300-400 bricks per hour, roughly 5 times more than a human’s 60 to 75 bricks an hour, which means it could boost productivity and reduce budgets on projects – plus free up workers’ time to focus on more complex tasks.

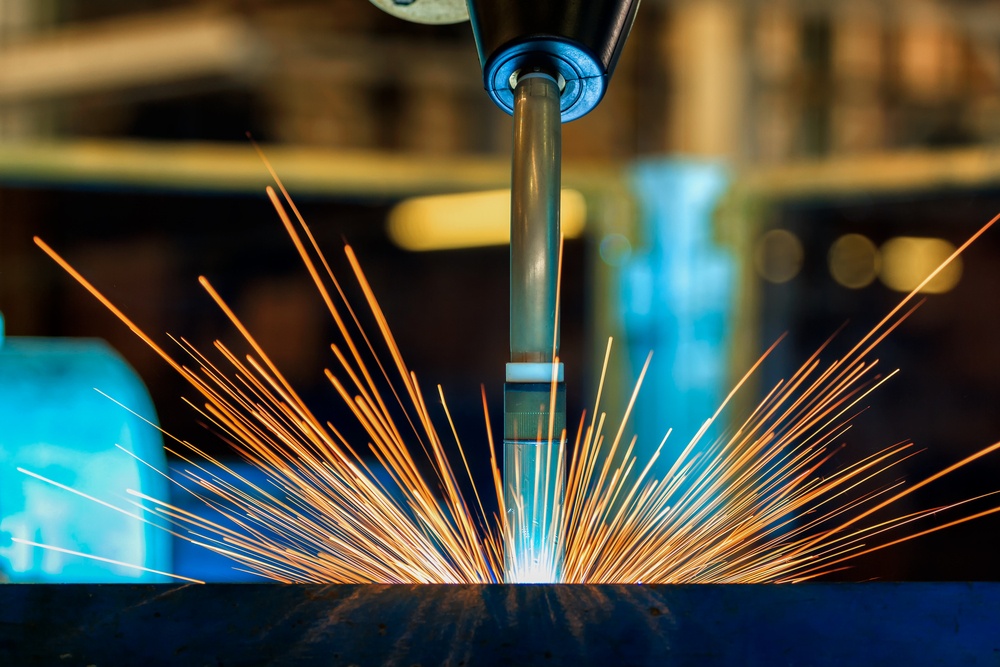

2. Robotic welding

Robotic welding is one of the most advanced applications of construction robotics, and can now be used across a wide range of industrial projects from metalworking in cars, to welding plastics. Using a mechanised arm, welding positioner, and robot controller, robotic welders can quickly and accurately weld together a variety of materials and only need a handful of people to oversee the work.

Not only does robotic welding reduce injury risks for construction teams; it also reduces the amount of manpower needed on manual tasks, so project teams can focus on meeting timelines, managing budgets and ensuring productivity, and chasing any late payment claims from suppliers.

3. Artificial intelligence for construction mapping

For project managers, one of the most time-consuming and difficult tasks is to monitor on-site job progress – particularly on a large construction site. However, companies like Doxel are leveraging technology to make real-time tracking more efficient, using drones and rovers to map construction sites on a daily basis, and leveraging AI compare these photos with BIM models, 3D drawings, and project timelines, in order to track the progress of a project.

Based on this data, the AI can identify areas of a project that are falling behind or deviations between on-site work and models, so project managers can quickly eliminate errors and rework, and track project timelines and budgets accordingly.

4. 3D printing robots

3D printing is already making waves in the design and architecture industry, and now this technology is leaving its mark on construction. The first ever 3D printed bridge was recently built in the Netherlands, using a mobile robotic arm that controls a 3D printer and a set of preprogrammed instructions – plus, other prototype 3D printing robots now have the ability to build an entire building that’s structurally safe.

As 3D printing and robotics technology continue to improve, there will be more opportunities for the construction industry to automate entire parts of the building process – which in turn improves productivity and reduces project budgets.

5. Automated demolition robots

Demolition work is notoriously unsafe, with Work Health and Safety risks ranging from unplanned structural collapse to falls, or damage to essential services. Thankfully, one of the recent innovations in construction robotics is tackling this: robots such as Husqvarna can demolish entire building sites, as well as fit into small areas that construction workers often struggle to reach. Demolition robotics is expected to be worth $321 million by 2022, making it a promising area of growth and an area of innovation that construction teams can take advantage of in the near future.

Demolition robots are slower than bringing in demolition crews to do the job manually, however they greatly reduce both OH&S risks and costs – making it a win-win for the industry.

6. Self-driving bulldozers

A company called Built Robotics has developed self-driving bulldozers which are capable of autonomously moving piles of dirt. Using sensors and self-driving technology, the bulldozer can grade earth on a construction site without needing workers on site to operate the machine, freeing up teams to focus on tasks that require more skill and finesse.

7. Rebar-tying robots

For many construction projects, rebar tying is not only time-consuming and costly – it is also monotonous, leading to strains and injuries in construction workers. Tybot, a rebar tying robot developed by Advanced Construction Robotics, Inc., can identify each section of rebar on a bridge, tie it, and move on to the next intersection – with only a few construction workers needed to place the rebar and oversee the robot’s progress.

So, what do you think?

The construction industry is undergoing a severe labour shortage, and robotics is one of the key ways that the industry as a whole is adapting to meet the increasing workload. Rather than replacing jobs, automation in construction will benefit the industry greatly as a whole, taking over dangerous or menial tasks, and allowing teams to focus more on skilled tasks and helping deliver projects in a timely manner within budget.

We may even see robots installing our very own tactile indicator studs soon! The possibilities for robotics in our industry are endless. With so many innovations in construction technology, automation and the robotics revolution will have a significant impact on the industry - and benefit construction workers and project teams both now and in the future.

Whether it’s leveraging technology for your next project, or managing your timelines and budgets, it’s important to ensure your projects are productive and cost-effective. Latham Australia’s ready-to-use project template pack makes project management a breeze – download it for free here.

To find out more about Latham products, please visit www.latham-australia.com. To talk to a Latham product expert, call 1300 LATHAM (528 426) or email sales@latham-australia.com.