Imagine if a single decision could have the same climate-saving impact as neutralising the carbon emissions of one million cars or four million cows. Project managers and sustainability officers would be hurriedly investigating ways to revolutionise the Australian construction industry… right?

Not quite - sustainability reform has yet to influence how construction companies dispose of construction and demolition (C&D) waste materials, as the cost to the environment is generally overshadowed by the cost of doing business. The Australian Government’s Construction and Demolition Waste Guide, however, explains how now is the most opportune time for construction businesses to invest.

“There are now, more than ever, clear opportunities for business and industry to invest in activities that will create profit and improve environmental outcomes by extracting valuable resources from the C&D waste stream.”

- Construction and Demolition Waste Guide, Australian Government

We understand you’re busy, so, we will be covering the top 5 materials that can be easily recycled from C&D waste. Use this menu to view the section most relevant to you, or continue to learn about all 5 materials.

Let’s dig in!

Where does construction waste go?

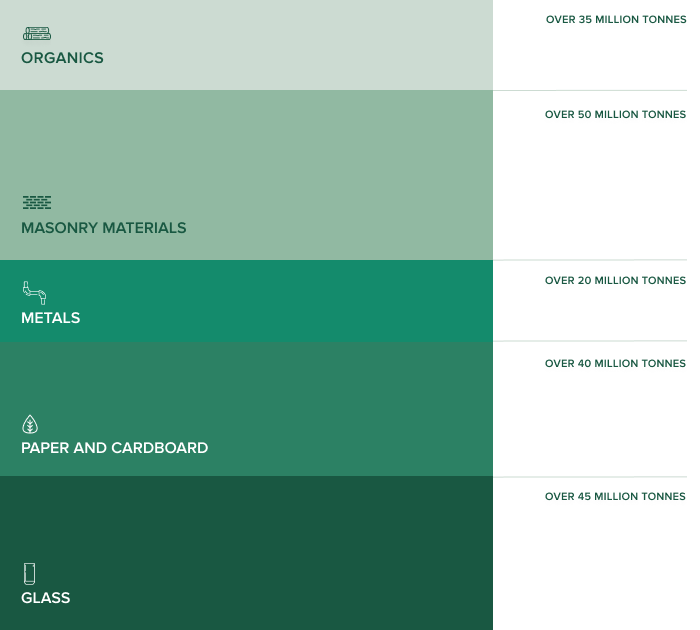

We know C&D waste materials are unavoidable; every building is made from concrete, wood, plasterboard, asphalt, metal and cardboard, often bordered by asphalt pavements to guide people from one place to the next. It would be unreasonable to expect a wasteless worksite due to the scope of these projects, order errors and adjusted calculations. But each of these six materials have something unexpected in common - together, they make up 70 to 95% of discarded C&D waste, destined to become landfill. Despite the documented financial benefits of recycling to a business’s bottom line - not to mention a greener planet - companies still aren’t on board.

Remember the scenario we discussed in the beginning? Less cars = less emissions? By recycling ordinarily refused C&D, the construction industry could have the same impact, and therefore bolstering their environmental credibility. But is the construction industry’s wastage situation really that bad? After all, cows and cars have nothing to do with plasterboard. While there’s plenty of room for improvement to go around, the 2018 Australian National Wastage report revealed C&D had the highest inflation, with an increase of 2% in the last 11 years. It doesn’t mean much on the surface, but what does a 2% inflation look like on the garbage pile?

Glass wastage alone is enough to create four billion square metres of recycled glass for future builds and projects. The general population are beginning to get the message, throwing away 10% less household waste per capita according to the same report, but what’s the disconnect in the construction industry? What are we missing?

Why aren’t we talking about construction and demolition waste recycling as a given instead of a concept?

Did you know plasterboard has the potential to release Hydrogen Sulfide, an extremely nasty gas that can lead to a tainted water supply if discarded incorrectly? It’s terrifying to think about the many ways in which your employees can be endangered by one wrong decision, but poor C&D disposal processes don’t just endanger people now, they threaten our planet and by extension, future generations. It can even open up your brand for legal action!

As a construction decision maker, you hold a lot of power. Although long term strategy takes time to action and implement, we are going to talk about some types of construction waste you can start recycling immediately.

Wood & Timber

Where can you find it?

The backbone of many construction projects, wood and timber is often ordered in surplus “just in case”, with anything left over classified as waste and trucked away at the end of the build.

How are wood and timber recycled?

Wood and timber leftovers can always be used for future projects. If time stretches too long between relevant builds, you can always recycle your remaining wood and timber or donate to a very grateful charity like Habitat for Humanity.

Why recycle wood and timber?

Estimates reveal nearly 2 million cubic meters of wood and timber meet the rubbish pile every year. By reducing this number and recycling excess, you’ll be saving trees, saving water and reducing landfill space by at least 238 cubic metres annually.

Plasterboard

Where can you find it?

Plasterboard (gyprock) is used to make the interior walls and ceiling cladding in most residential homes and commercial buildings.

How is plasterboard recycled?

Contractors can use this site allstar to plug holes, make wet concrete supports and treat newly laid garden beds - the boron infused plasterboard delivers a nutrient hit to hungry plants. Away from agriculture and ad hoc handiness, plasterboard can be recycled, becoming paperboard or more plasterboard!

Tip: Companies like REGYP offer cheaper and greener plasterboard waste recycling services.

Why recycle plasterboard?

Landfills are already bursting with plasterboard; by working on recycling your cast-offs, you’ll reduce project costs and alleviate the large percentage of this material burdening tips and dumps. Further, if you think plasterboard can breakdown in landfills, you may want to think again. Our previously mentioned boron infused plasterboard cannot break down without sunlight, so leaving it under piles of landfill won’t do the environment any favours.

Steel, copper pipes and wire

Where can you find it?

Over 20 million tonnes of metals exist in landfill. 95% is steel, while the remaining 5% includes materials like copper piping and wire. Metals aren’t worthless commodities - folks overseas scour anything from the household hoarding-closet to the local tip for copper and wire because they’re both worth a considerable amount of money. Some dishonest people even steal these metals from worksites to be used elsewhere or sold for scrap.

How are steel, copper pipes and wire recycled?

Copper is a finite resource; like all mined materials, we shouldn’t be taking more than we need. This resilient metal can be flattened, shredded and reused easily without losing condition. Copper recycling strategies can be implemented with each new product design to drive end of life recovery, recycling processes and overall yields.

Why should this material be recycled?

Copper lasts a long, long time. Studies estimate two-thirds of the 550 million tonnes of copper mined since 1900 is still being actively and productively utilised. Despite its longevity, copper does have its drawbacks - mining can release dust and waste gases, like sulphur dioxide, that are harmful to people, animals and the environment, so best to use what’s already been mined and recycle!

Bricks

Where can you find it?

Bricks have a lifespan of more than 200 years - like copper, bricks are here to last the distance. You can reclaim or recycle bricks and blocks which have previously been used in the construction of buildings, walls, paving and infrastructure, like bridges and sewers.

How are bricks recycled?

Unwanted bricks are often recycled in two different ways.

- They can be cleaned and reused for a different construction project.

- They can be crushed into brick chips or finer materials for use in manufacturing road-base, track and drainage material, fill sand or for new bricks.

Why should bricks be recycled?

Australian construction companies dump 8 million tonnes of bricks into landfill each year. In real terms, that not-so-nice 8 million is equivalent of saving 1.5million households from their energy bill for a month. Recycling bricks minimises the need for mining and quarrying activities to produce new bricks and diverts significant quantities of waste materials from landfill.

Glass

Where can you find it?

In the surplus pile. Glass is the material most likely to be ordered in abundance - breakage and damage during storage and installation demand construction companies have a backup pane or three ready to go.

How is glass recycled?

Recycling glass is relatively easy and straight-forward. To get you started, we’ve compiled a list of suggestions, from staff training to order management:

- Provide staff with up-to-date training, ensuring they know how to handle glass safely to minimise breakages.

- Implement a separate area or bucket for glass wastage, avoiding damage and contamination.

- Provide dedicated storage areas to reduce the risk of damage.

- Arrange for materials to be delivered at the time and place on site they are required to reduce the risk of breakage during handling and storage

- Arrange transport to move glass waste to cullet collection centres

- Keep records to prevent over-ordering and minimise stock held on site

Why should glass be recycled?

The cost savings of recycling is in the use of energy. Compared to making glass from raw materials for the first time, cullet melts at a lower temperature. So we can save on energy needed to melt the glass. Additionally, glass produced from recycled glass reduces related air pollution by 20% and related water pollution by 50%.

What will the use of waste material in building construction mean for you the next financial year?

Recycling doesn’t have to be a headache. By making these five changes, you’ll be building a healthier foundation for the planet while piecing together the homes, offices and other buildings we take for granted every day. Which materials can you see your business tackling first? Will you reuse, recycle or donate?

Quick takeaways

- Rethink: Practice deconstruction instead of demolition

- Reduce: Calculate the savings

- Refuse: Build to standard dimensions

- Reuse: Build it back into the building

- Recycle: Locate your local recycling centre

To find out more about Latham products, please visit www.latham-australia.com. To talk to a Latham product expert, call 1300 LATHAM (528 426) or email sales@latham-australia.com.