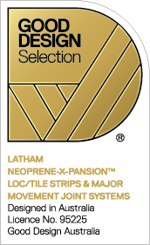

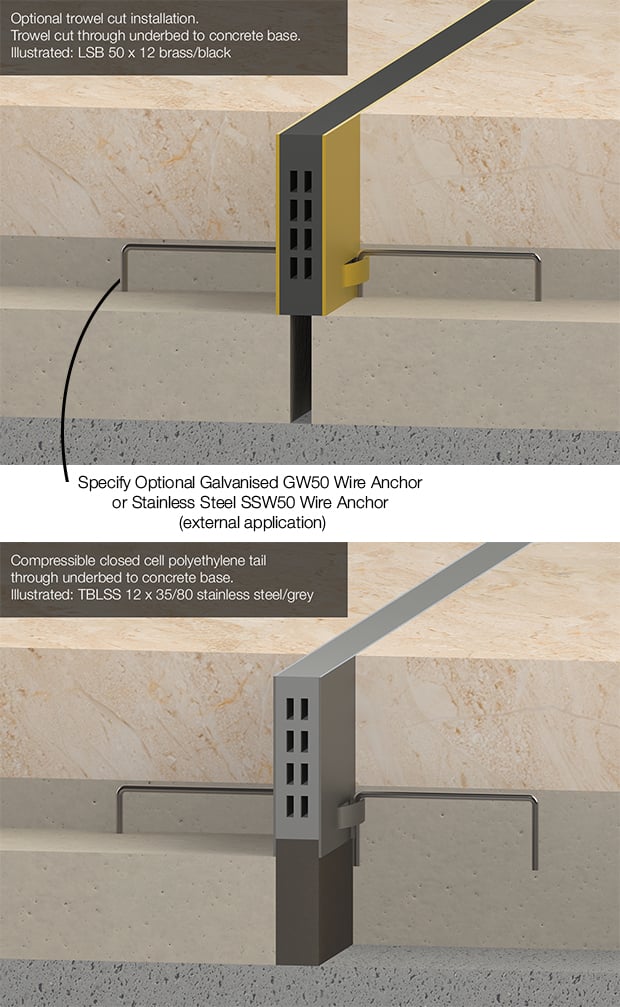

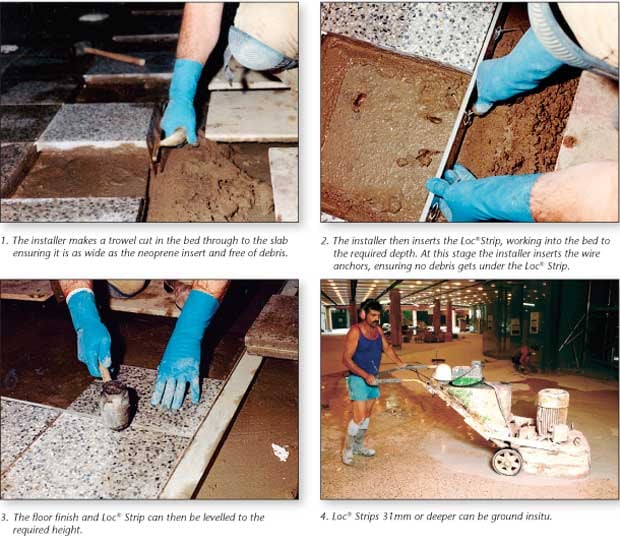

The illustrations and photographs on these pages show the correct anchoring procedures using the GW50 or SSW50 Wire Anchors with the Latham Neoprene-X-Pansion Loc Strip. All Loc Strips are 1800mm in length and require wire anchors at 350mm centres for secure fixing and maximum expansion/contraction control. All Loc Strips must be installed in accordance with best practice. Brass, rebonite and stainless steel are used both internally and externally. Zinc is for internal applications only. When specifying always state neoprene colour required after product type. If requiring non-standard Loc Strips please consult with Latham Australia.

Installation of Loc Strips in mud bedded tile and paver applications

All Loc Strips and Tile Strips should be installed level with surrounding floor finish and not more than 0.5mm below floor finish. Strips should never be installed above the surrounding floor finish.

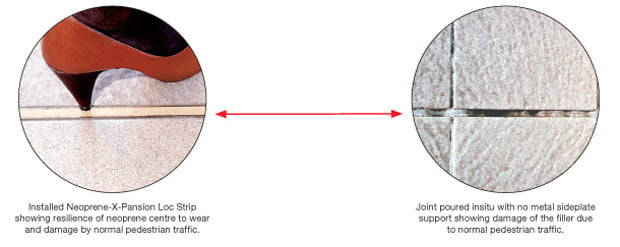

Comparison with poured insitu

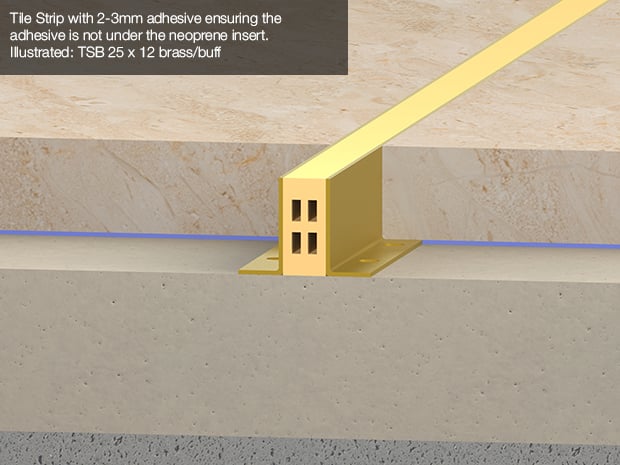

Tile Strip Installation - Brass, Aluminium, Stainless Steel

Tile Strips are designed to be installed when using adhesive fixed tiling. Standard tile strips are generally installed with 2-3mm of adhesive. It is imperative that the installer assures that adhesive is not under the neoprene insert as this will stop the neoprene moving.Tile Strips should be installed over joints or saw-cuts while the adhesive is in a plastic state and troweled firmly to ensure adequate anchorage. To confirm that the location of joints in tile work align with existing substrate joints, the tile work joints should be constructed during installation of the mortar and tile beds, rather than by saw-cutting joints after installation. Joint depth should be appropriate for the combined thickness of the adhesive layer and the tiles, and to prevent the joint protruding above the level of surrounding tile work.