Accessories - Fixing

Colour-Matched Stainless Steel Screws

As standard, all Latham Stair Tread Nosings are cut to site-required sizes; all cut-to-size nosings will be supplied with 31mm x 8G Stainless Steel Screws for fixing at standard 250mm centres, with colour-matched powder coated heads, together with suitable rawl plugs, as standard. On request, stainless steel or brass screws with natural heads can be supplied in 25mm or 38mm lengths.

Plastic Plugs

To suit 8 Gauge screws .

Tamper-Proof Fixing

For all situations where the detachment of the stair treads must be avoided for safety or security reasons, Lathams can supply 37mm x 8G screws with our special tamper-proof head. Supplied with matching driver bits. These are not standard Allen (Hex) Keys. Only available in stainless steel with natural finish.

Stainless Steel Countersunk Head Metal Thread Screws and Nuts

When fixing through steel or similar and there is access under the tread, Latham can supply 3/16” machine screws and nuts. Lengths 16mm, 25mm (standard) and 37mm.

When Rufazel is being supplied, fixings will be ¼” galvanised fixings, when supplied as standard the machine screws will have a mushroom head and nut. On request and for metal mesh style industrial stairs, a spring washer and saddle clip can be supplied

Saddle Clip

Levelling & Bedding Adhesives For Stair Treads & Mall Bars

Lathams recommend the use of adhesives in association with mechanical fixings for all applications on timber, tile, stone, concrete and other similar substrates. When installing on hard surfaces like those mentioned, it is not good enough to use mechanical fixings alone, as often the substrate is not flat and level, often mechanically fixed nosings will creak and flex as traffic travels over them when they do not have a suitable adhesive used. Following are details of the adhesives and levelling compounds that Latham specifically manufacture for use with our range of Asbraloy and Asbrabronz safety flooring products.

Titazel™ Thixotropic Epoxy Resin Adhesive

Titazel Thixotropic Epoxy Resin Adhesive is a 2 part epoxy resin supplied in a 1.5kg kit. Installation rate per kit for 75mm tread sections and smaller approximately 25 lineal metres, for 135mm sections, approximately 18 metres. The resin compound in the larger kit should have a consistency and look similar to petroleum jelly. Once the full can of hardener is mixed into the kit it will have the consistency of viscous honey. Apply the material after following the mixing instructions on the tin, to the underside of the stair tread nosings or inserts, then following the installation instructions, install the tread. Be sure to clean up any excess epoxy before it cures with Asbra Titazel™ Clean up solvent. Ensure the treads are not walked on for 12+ hours.

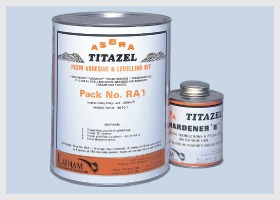

Titazel™ RA1 Epoxy Resin Filling and Levelling/Repair Adhesive Kit

Titazel RA1 Epoxy Resin Filling and Levelling/Repair Adhesive Kit is a 2 part epoxy resin compound supplied in a 3.5kg kit. Each kit will cover approximately 2 square meters at 1mm thick. The resin compound in the larger kit should have a consistency and look similar to a slightly wet cement mix. Once the full can of hardener is mixed into the kit it will have the consistency of brick layer’s mortar. After following the mixing instructions on the tin, apply RA1 to repair any worn or broken sections on the treads. This material can be used as both a simple levelling compound with the treads applied later or the treads can be applied at the time of repairing using the RA1 as an adhesive as well. This procedure may require the treads to be carefully packed to the correct height with builder’s packers or similar prior to the application of the RA1. Be sure to clean up any excess epoxy before it cures with Asbra Titazel™ Clean up solvent. Ensure the treads are not walked on for 12+ hours.

Asbra Titazel Clean Up Solvent

Removes uncured resins or cartridge adhesive during installation. Can also be used to wipe off underside of tread nosings before adhesive fixing for better bond. 4 litre and 500 ml.

Tytred 2 Bedding Adhesive

Tytred 2 Bedding Adhesive is a quick and easy product to bond and bed the Asbraloy and Asbrabronz nosings with hard surfaces like concrete, tile, stone, timber and other similar substrates. The bedding adhesive forms a layer between the nosing and the substrate which helps reduce traffic noise and rattle which can often occur with even the tightest mechanically fixed nosing. The noise and rattle generally occurs because the aluminium and brass stair tread nosing extrusions are very straight, while the substrate will often vary, causing noise and rattle. Tytred2 must always be used with mechanical fixings. The cartridges of Tytred2 are 300grams and fit in a standard sealant applicator gun. The coverage for Tytred 2 is approximately 4.6 metres per cartridge for nosings 75-100mm in depth on a level step that is not hollow or worn. For more secure bonding, Latham recommend Titazel Thixotropic Epoxy Resin Adhesive and Titazel™ RA1 Epoxy Resin Filling and Levelling/Repair Adhesive. Be sure to clean up any excess Tytred2 before it cures with Asbra Titazel™ Clean up solvent. Ensure the treads are not walked on for 30-60 minutes depending on porosity of the substrate.

Tytred 2 Bedding Adhesive is a quick and easy product to bond and bed the Asbraloy and Asbrabronz nosings with hard surfaces like concrete, tile, stone, timber and other similar substrates. The bedding adhesive forms a layer between the nosing and the substrate which helps reduce traffic noise and rattle which can often occur with even the tightest mechanically fixed nosing. The noise and rattle generally occurs because the aluminium and brass stair tread nosing extrusions are very straight, while the substrate will often vary, causing noise and rattle. Tytred2 must always be used with mechanical fixings. The cartridges of Tytred2 are 300grams and fit in a standard sealant applicator gun. The coverage for Tytred 2 is approximately 4.6 metres per cartridge for nosings 75-100mm in depth on a level step that is not hollow or worn. For more secure bonding, Latham recommend Titazel Thixotropic Epoxy Resin Adhesive and Titazel™ RA1 Epoxy Resin Filling and Levelling/Repair Adhesive. Be sure to clean up any excess Tytred2 before it cures with Asbra Titazel™ Clean up solvent. Ensure the treads are not walked on for 30-60 minutes depending on porosity of the substrate.Aluminium & Brass Stair Tread Cutting Wheels

The aluminium and brass Abrasive Stair Tread Cutting Wheels are exclusively manufactured for cutting Latham Stair Tread sections. The fine grade silicon carbide fabric enclosed and wax encrusted blades create the best cut available for the treads when multiple cuts are required (standard metal cutting blades will be damaged by the abrasive inserts in the stair treads). The cutting wheels are designed to be used on a drop or friction saw with maximum RPM of 3400. The new wheel diameter is 355mm, with a bore size of 25.4mm.These cutting wheels are available for purchase from Latham Australia when the material is supplied in full 4600mm manufacturing lengths for site cutting to the required sizes. On a properly set up drop saw, you should expect approximately 90 cuts for 75mm-100mm wide treads from 1 blade (different saws will achieve different results).

Cleaning and Maintenance

Latham recommend that Gold-Chem Neutral pH Concentrated Cleaner be considered for washing and maintaining the appearance of all Latham Asbraloy and Absrabronz Stair Tread Nosings. In our experience no cleaner, detergent or soap has ever performed like Gold-Chem™. This highly concentrated powder is mixed with water in appropriate proportion and applied to the surface. In minutes with light brushing the chemical loosens dirt marks and most stains.

Gold-Chem will not effect the bond between the treads and the step or substrate, or break down the Suregrip or Supagrit mineral inserts which can be the case with some harsh commercial cleaners.

Latham recommend that all treads be at least mechanically fixed, and where possible also be adhesive fixed, see details below. From time to time or when vibration becomes apparent the fixings should be checked and tightened as required.